There are different translucent aluminum constructions and different projects of glazing facades. Structural glazing is a form of continuous glazing, and in general is something between the spider type of facade cladding and mullion-transom type. This type of glazing gives the highest degree of transparency of the facade, compared to traditional glazing, stained glass and other options.

In structural glazing glass panels are connected by anchors to the structure of the building directly without removable plates or covers. The glass can be absolutely of any kind, even triple glazing. Thanks to the structural glazing, the facade looks unified.

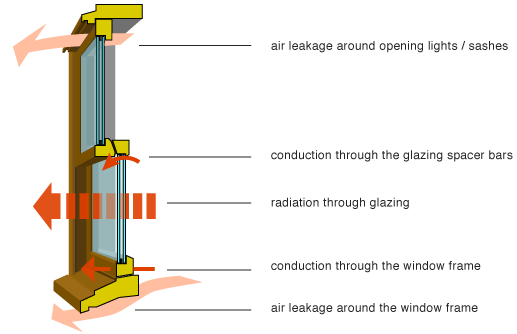

It is believed that with structural glazing to achieve energy efficiency of the premises is much easier due to the reduction of heat loss of the building. The fact that the space between the insulating glass units is treated with a special sealant, so the structure not only looks unified, but also functions as one whole. In addition, the bare metal frame of the building has been reduced (or completely eliminated), which also improves the thermal efficiency. In addition, the penetration of moisture and air into the room through the facade is eliminated (or reduced), i.e., the maximum insulation of the building is achieved.

So structural glazing not only provides the best visual qualities to the building from the outside and inside, but also serves as the best insulator and a means to achieve thermal efficiency.

The quality of structural glazing depends on the engineers who design it as well as the builders who install it. In general, these are the two main factors that affect the success or failure of a translucent structure. In other words, only companies with good experience should be allowed to design and install glazing. Do not also forget that the suppliers of insulating glass units, metal elements, fasteners and sealants play a major role in the «composition» of high-quality facades. However, designers and installers who provide glazing service, most often already have a proven relationship with producers of materials for their work (or have their own production to meet the needs of clients).